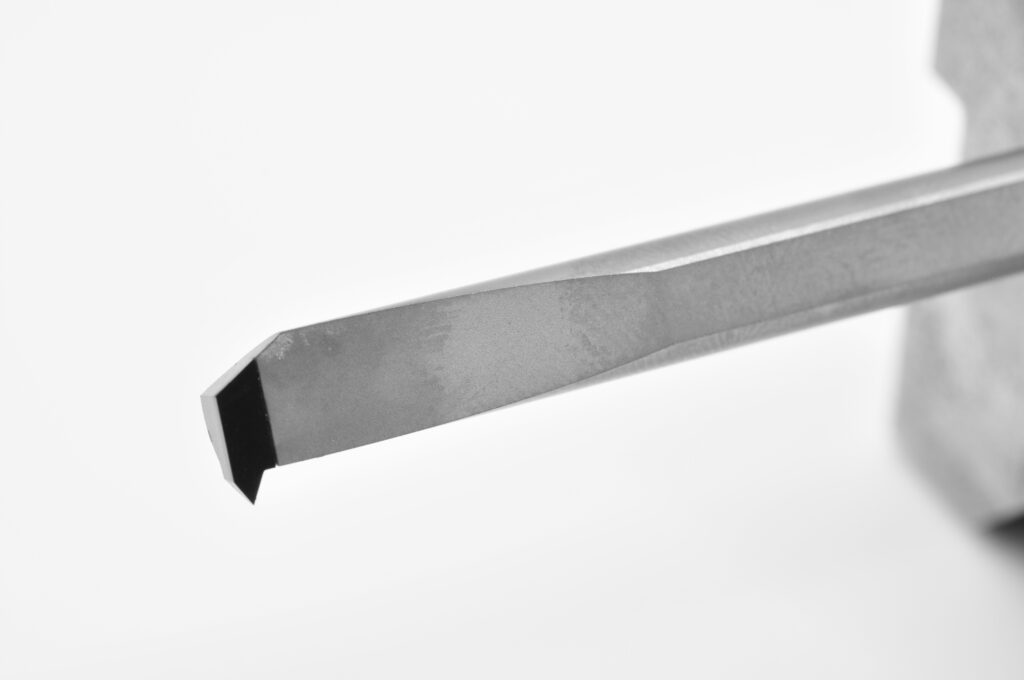

Diamond Tipped Threading Tool; Replicating a Carbide Blank

Project Date: Feb 2024

This threading tool was ordered by one of our long-standing customers, who machines composites such as Torlon, PEEK, and other high-performance polymers. Originally, they were using a carbide tool (Internal Tool #08-1500) but wanted to switch to PCD.

Our typical process involves purchasing an existing carbide blank that the customer desires, adding a pocket/slot for the diamond, brazing/soldering the diamond, and finishing it to the customer’s specifications. Usually, we would buy the carbide “blank” from the manufacturer and then attach the PCD tip to it. However, we cannot diamond-tip these tools because they already have a brazed carbide tip. Therefore, we had to get creative and manufacture our own carbide blanks from scratch to essentially replicate the existing carbide threading tool.

Fortunately, we have a great team at National Diamond, and we were able to make this happen despite the additional challenge of starting from square one with the carbide production.

More Information on Threading Tools

Threading tools are cutting tools used in machining operations to create external or internal threads on cylindrical workpieces. These tools are essential for manufacturing threaded components such as bolts, nuts, screws, and other threaded parts. Here’s an overview of threading tools:

Types:

External Threading Tools: These tools are used to cut threads on the external surface of a workpiece. They come in various designs, including single-point threading tools, die heads, and thread milling cutters.

Internal Threading Tools: Internal threading tools are used to cut threads inside pre-drilled or pre-machined holes. They include taps for cutting internal threads directly and boring bars with threading inserts for machining threads in pre-drilled holes.

Tool Geometry:

Threading tools have specific geometries tailored to the type of threads being cut. For example, V-shaped cutting edges are common for cutting standard metric or imperial threads, while square or rectangular cutting edges may be used for square threads.

The geometry of the cutting edge determines the thread profile, pitch, and angle, ensuring precise and accurate thread cutting.

Thread Cutting Methods:

Threading tools can cut threads using various methods, including single-point threading, thread milling, tapping, and thread rolling. The selection of the method depends on factors such as the type of threads, material, machining complexity, and production volume.

Threading tools come in a wide range of sizes, shapes, and configurations to accommodate different thread specifications, materials, and machining requirements. Proper selection, setup, and maintenance of threading tools are crucial for achieving accurate and high-quality threaded components in machining operations.